Welcome OEM!

Welcome OEM! Kindly inform us following information

1, Photo

2, ID, OD, Height

3, Filtration Precision

4, End Cap

Our services

- 1.Customers design are also available

- 2.Prompt delivery of the sample and bulk production

- 3.Good quality control procedure and production line are set up

- 4.Professional experience on the filter

- 5. For more details, welcome to contact with us

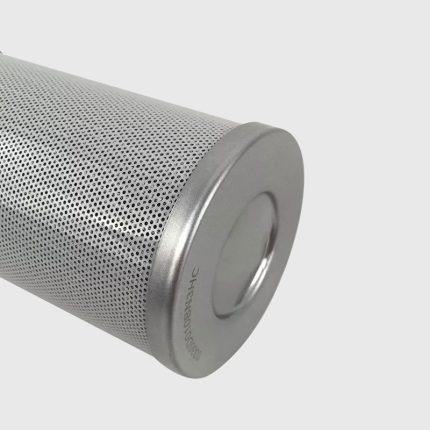

Product Description

|

Model

|

Customized

|

||

|

Filter material

|

stainless steel mesh

|

||

|

Filtration rate

|

customized

|

||

|

Working medium

|

hydraulic oil

|

||

|

Flow tate

|

customized

|

||

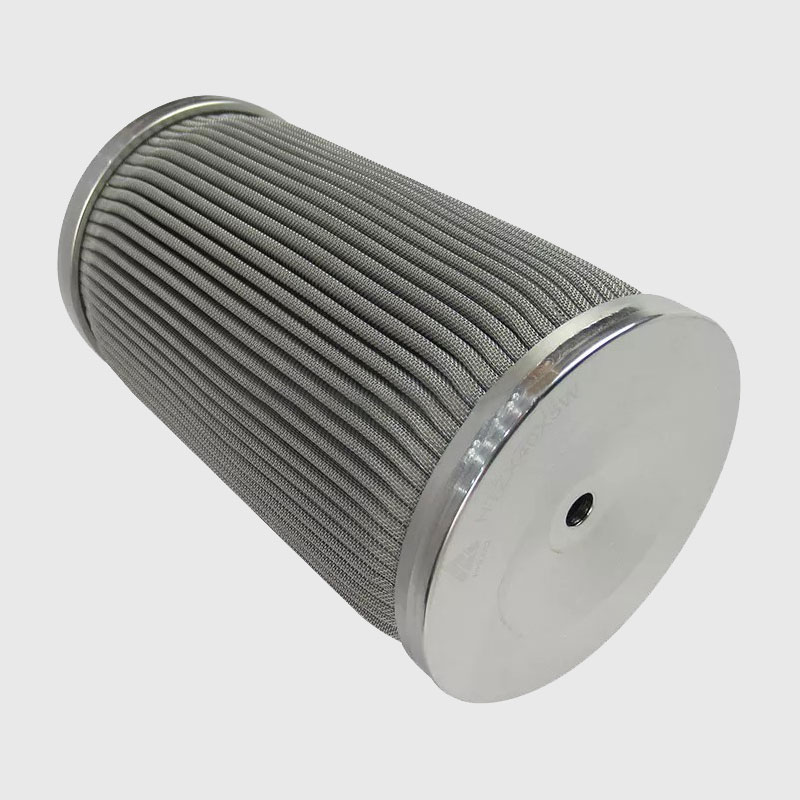

High quality polymer stainless steel melt blown filter element

Hydraulic oil filter is used in various oil systems to filter out solid impurities generated by external mixing or system operation. It is mainly installed on the oil absorption road, pressure oil line, oil return line, bypass, and separate filtration system in the system.

Notes:

2. Please contact us to make optimal filtration solutions of your applications.

Feature

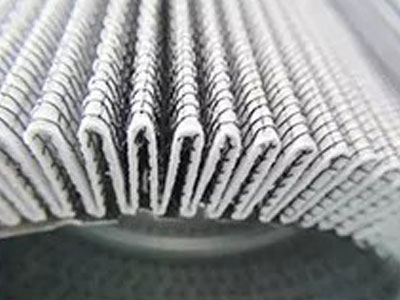

- 1 good filtration performance, uniform particle filtration performance for 2-200μm filtration particle size;

- 2 good corrosion resistance, heat resistance, pressure resistance and wear resistance;

- 3 stainless steel filter element pores uniform, accurate filtration accuracy;

- 4 stainless steel filter unit has a large flow per unit area;

- 5 stainless steel filter element for low temperature, high temperature environment; can be reused after cleaning, no replacement

Material feature

Stainless steel melt filter is mainly made of stainless steel woven mesh and stainless steel fiber sintered felt. It has the characteristics of smooth channel, easy cleaning, high temperature resistance, corrosion resistance, no falling off of the wire mesh, high porosity, good gas permeability, strong dirt holding capacity and strong regeneration ability.

Malntenance

- 1. Put off the original hydraulic oil before changing, check the oil return filter, oil absorption filter, pilot filter to see if there are iron filings or other impurities, if there are hydraulic components failure, after cleaning, cleaning system .

- 2. When changing hydraulic oil, all hydraulic oil filter elements (return oil filter, oil suction filter, pilot filter) must be replaced at the same time, otherwise it is equivalent to no change.

- 3. Identify the hydraulic oil label. Different grades and different brands of hydraulic oil are not mixed, and may react to deteriorate and produce floc. It is recommended to use the excavator to specify oil.

- 4. Before the refueling, the oil-absorbing filter element must be installed first. The nozzle that is covered by the oil-absorbing filter element leads directly to the main pump. When the impurity is light, the main pump wears up, and the pump is pumped.

- 5. Refueling to the standard position, the oil tank generally has an oil level gauge to see the liquid level gauge. Pay attention to the parking mode. Generally, all the cylinders are fully retracted, that is, the arm and bucket are fully extended and landed.

- 6. After adding the oil, pay attention to the main pump to discharge air, otherwise the light will temporarily stop the whole car, the main pump will be abnormal (air blast), and the air hole will damage the main pump. The air exhaust method is to loosen the pipe joint directly on the top of the main pump and directly fill it up.

Product Display

Our products through the following test

- ISO 2941 Collapse & Burst Resistant

- ISO 2942 Material Compatibility with Fluids

- ISO 2943 Material Compatibility with Fluids

- ISO 3724 Flow Fatigue Characteristics

- ISO 3968 Pressure Drop vs. Flow Rate

- ISO 16889 Multi-pass Performance Testing

Quality Assurance

- 1. Best raw materials, best technology.

- 2. Our products are produced strictly in accordance with the requirements, and there are special personnel for test before leaving the factory.

- 3. High efficiency and high precision to ensure the equipment safety.

Filter Material

Framework

End Cap

Rubber Gasket

Galvanived Mesh

Glass Fiber

Fold The Pleats

Packing & Delivery

Contact Us

Hydraulicoilfiltration Focus on the research and development, production and sales of hydraulic oil filtration and oil filtration equipment, and continue to invest in hydraulic oil filtration technology innovation.

We have the right filters, contamination control products and capabilities to protect machinery and components in hundreds of applications – in the factory and on heavy-duty equipment. we can solve any filtration challenge, big or small.

Especially suitable for large equipment manufacturing plants, metal processing plants, machine tool plants, steel plants, forging plants, automobile and accessories factories, etc…

- Professional manufacturer with many years’ experience

- Good quality with competitive price

- OEM & ODM are welcome

- Produce according to your sample or drawing

- Various payment items are acceptable

- Good service by experienced manager

- Each product is individually under strict inspection

- On-time delivery

- Small MOQ is acceptable

451 Wall Street, UK, London

Phone: (064) 332-1233

Fax: (099) 453-1357

Reviews

There are no reviews yet.